The mainstream production process of boost DC-DC converters is an electronic device used to increase the DC voltage, widely used in electronic equipment, communication equipment, automotive electronics and other fields. In modern industrial production, the production process of boost DC-DC converters has become very mature. After years of development and improvement, a complete set of production processes and technical standards has been formed.

1. Design and planning: Before production, product design and planning are required to determine the product's function, performance requirements, external dimensions, and other parameters. Designers need to design a solution that meets the requirements based on customer and market needs.

2. Component procurement: After determining the product design solution, various components need to be procured, including inductors, capacitors, diodes, transistors, etc. The quality and performance of these components directly affect the stability and reliability of the product.

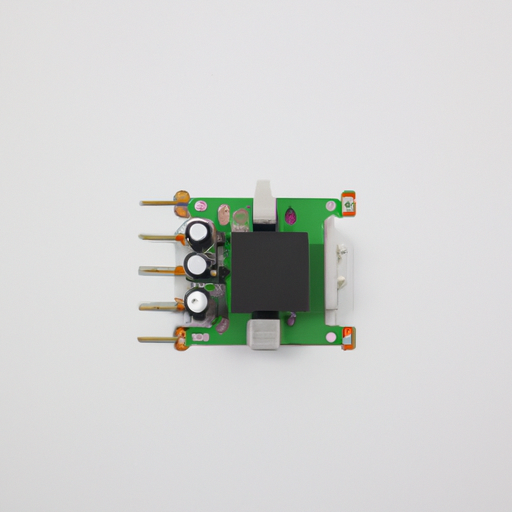

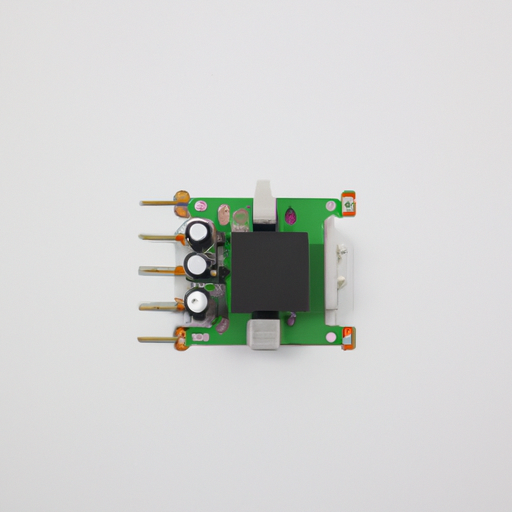

3. PCB design and production: According to the product design solution, design the PCB circuit board, layout various components on the circuit board according to the design requirements. Then have the PCB manufactured by a PCB manufacturer to meet the requirements.

4. Component soldering: Solder the purchased components to the PCB circuit board to ensure correct and error-free connections between components. The soldering process needs to strictly control temperature and time to avoid component damage or poor soldering.

5. Debugging and testing: After soldering the components, the circuit needs to be debugged and tested to ensure normal operation. Various parameter tests, such as output voltage, output current, efficiency, etc., are performed on the circuit using testing instruments.

6. Encapsulation and assembly: After completing circuit debugging and testing, the circuit needs to be encapsulated into finished products, including casing, heat sink, etc. Then assemble the various components together to form the final product.

7. Quality inspection and packaging: Finally, the finished products need to undergo quality inspection to ensure they meet the standard requirements. Then package the products as finished products, ready for shipment to customers.

In summary, the production process of boost DC-DC converters is a complex process that requires coordination and cooperation in various aspects. Only by strictly following the standard process can the quality and performance of the product be guaranteed. With the continuous development of technology, the production process of boost DC-DC converters is also constantly improving and perfecting to meet market demands and customer requirements.

The mainstream production process of boost DC-DC converters is an electronic device used to increase the DC voltage, widely used in electronic equipment, communication equipment, automotive electronics and other fields. In modern industrial production, the production process of boost DC-DC converters has become very mature. After years of development and improvement, a complete set of production processes and technical standards has been formed.

1. Design and planning: Before production, product design and planning are required to determine the product's function, performance requirements, external dimensions, and other parameters. Designers need to design a solution that meets the requirements based on customer and market needs.

2. Component procurement: After determining the product design solution, various components need to be procured, including inductors, capacitors, diodes, transistors, etc. The quality and performance of these components directly affect the stability and reliability of the product.

3. PCB design and production: According to the product design solution, design the PCB circuit board, layout various components on the circuit board according to the design requirements. Then have the PCB manufactured by a PCB manufacturer to meet the requirements.

4. Component soldering: Solder the purchased components to the PCB circuit board to ensure correct and error-free connections between components. The soldering process needs to strictly control temperature and time to avoid component damage or poor soldering.

5. Debugging and testing: After soldering the components, the circuit needs to be debugged and tested to ensure normal operation. Various parameter tests, such as output voltage, output current, efficiency, etc., are performed on the circuit using testing instruments.

6. Encapsulation and assembly: After completing circuit debugging and testing, the circuit needs to be encapsulated into finished products, including casing, heat sink, etc. Then assemble the various components together to form the final product.

7. Quality inspection and packaging: Finally, the finished products need to undergo quality inspection to ensure they meet the standard requirements. Then package the products as finished products, ready for shipment to customers.

In summary, the production process of boost DC-DC converters is a complex process that requires coordination and cooperation in various aspects. Only by strictly following the standard process can the quality and performance of the product be guaranteed. With the continuous development of technology, the production process of boost DC-DC converters is also constantly improving and perfecting to meet market demands and customer requirements.